Industry information

Company News

- Punched aluminum veneer: the perfect combination of creativity and aesthetics

- Aluminum veneer: the "invisible" art in modern architecture

- Punched aluminum veneer, infinite creative architectural beauty

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: the green choice for modern architecture

Industry dynamics

- Aluminum veneer customization: creating a unique space aesthetic and new fashion trend

- Design and installation of aluminum veneer curtain wall

- Aluminum veneer, the fashionable new darling of modern architecture

- The charm of aluminum veneer: not just metal, but also art

- Aluminum veneer customization, create your own personalized space!

Frequently asked questions

- How to choose a suitable aluminum veneer supplier?

- What is the environmental performance of aluminum veneer?

- What are the precautions for the design and installation of aluminum veneer curtain walls?

- What is the market outlook and development trend of aluminum veneer?

- How to improve the practicality of aluminum veneer through innovative applications?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Screen printing process for 2.5mm aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-04 15:35:06

- Click:0

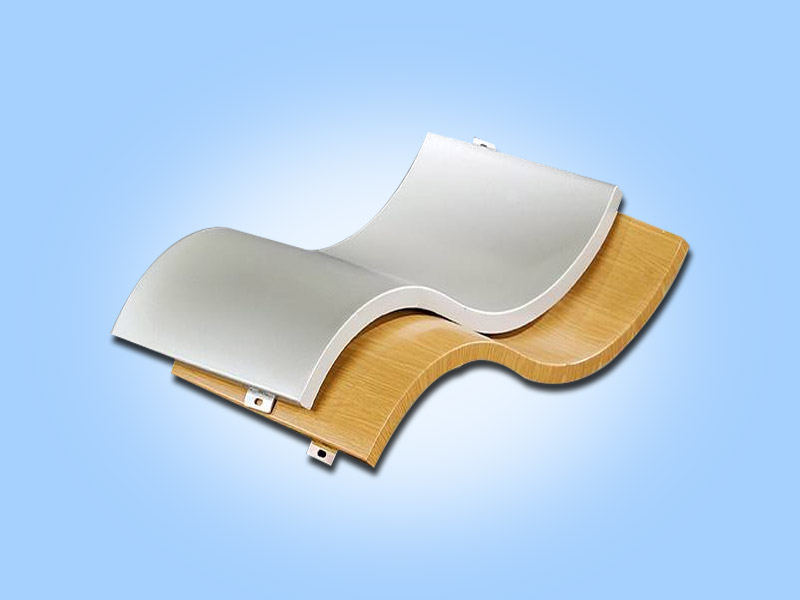

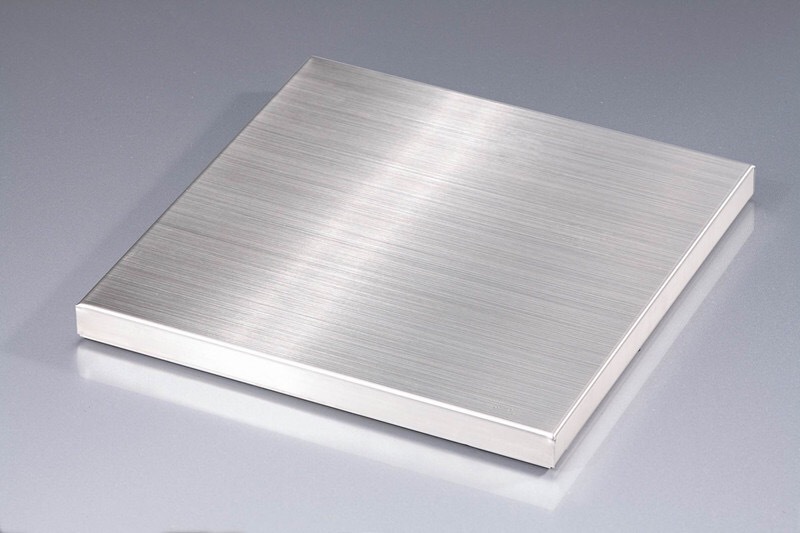

With the development of the architectural decoration industry, the application of 2.5mm thick aluminum veneer is becoming increasingly widespread. In addition to conventional surface treatment methods, screen printing technology has also become one of the commonly used surface treatment methods. The following will provide a detailed introduction to the screen printing process of 2.5mm thick aluminum veneer.

1、 Principles of Screen Printing Technology

Screen printing is a technology that uses a screen to print on the surface of a substrate. In the screen printing process of 2.5mm thick aluminum veneer, it is necessary to first prepare a printing equipment with screen and ink, and then install the equipment on the surface of the substrate to form a layer of pattern or text on the surface of the aluminum veneer through printing, ultimately forming the desired decorative effect.

2、 Screen printing process flow

1. Prepare printing equipment: Design and manufacture as needed to ensure the quality and specifications of the screen match, as well as the quality and specifications of the ink match.

2. Cleaning the substrate: Use appropriate cleaning agents to clean the substrate to remove surface dirt and grease.

3. Install printing equipment: Install the prepared printing equipment on the surface of the substrate, ensuring correct position and orientation.

4. Adding Ink: Add ink to the screen and adjust parameters such as pressure and printing distance to achieve the desired printing effect.

5. Printing: Ink is evenly printed on the surface of aluminum veneer through screen printing, forming a layer of pattern or text on its surface.

6. Follow up processing: Perform subsequent processing as needed, such as drying, to enhance the decorative effect.

3、 Precautions

When performing screen printing process on 2.5mm thick aluminum veneer, the following points should be noted:

1. It is necessary to choose and match according to actual needs and usage environment to ensure that the decorative effect meets the expected requirements.

2. When selecting materials and processing, attention should be paid to the matching of quality and specifications to avoid situations where problems cannot be solved.

3. During the construction process, it is necessary to pay attention to the implementation of safety protection measures to prevent accidental injury accidents.

4、 Summary

The screen printing process of 2.5mm thick aluminum veneer is one of the important factors affecting its application effect. When carrying out screen printing technology, it is necessary to pay attention to the preparation work, correct selection and matching of materials, and strict quality inspection to ensure that the product meets the expected requirements. At the same time, it can also be reasonably matched and used according to market demand and aesthetic standards to enhance the beauty and added value of the product.

Customer service QQ

Customer service QQ