Industry information

Company News

- Aluminum veneer customization, creating exclusive space aesthetics

- Aluminum veneer: the "lightweight" choice for modern architecture

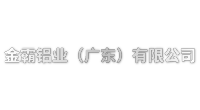

- Exploring perforated aluminum veneer: the new favorite of architecture with infinite creativity

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm!

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Production cost and market price of aluminum veneer

- Aluminum veneer design creates a unique spatial aesthetic

- Improvement and development trend of production process for aluminum veneer

- Punched aluminum veneer: artistic embellishment in the world of aluminum materials

Frequently asked questions

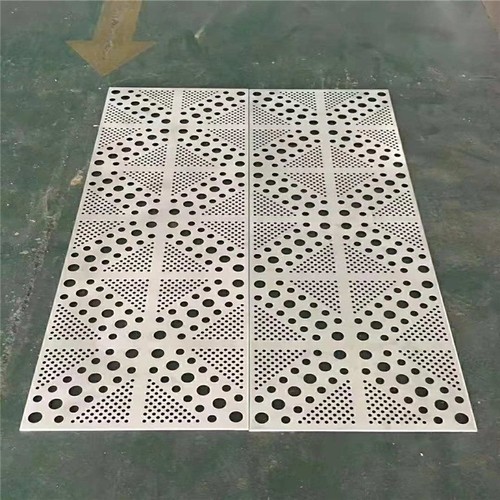

- What is aluminum veneer?

- How to choose a suitable aluminum veneer supplier?

- What is the market outlook and development trend of aluminum veneer?

- What are the precautions for the design and installation of aluminum veneer curtain walls?

- How to improve the practicality of aluminum veneer through innovative applications?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Technological innovation and development trend of carved aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-14 17:05:56

- Click:0

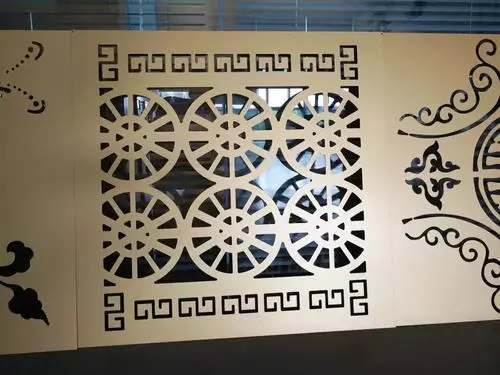

With the continuous advancement of technology and the continuous development of society, carved aluminum veneer, as a new type of building decoration material, is also constantly undergoing technological innovation and research on development trends. Below, we will provide a detailed introduction to the technological innovation and development trends of carved aluminum veneer.

1、 Process innovation

1. The application of CNC machining technology: The traditional carving and carving aluminum veneer manufacturing process requires a large amount of manual operation, which is inefficient and difficult to guarantee accuracy. The application of CNC machining technology can greatly improve production efficiency and accuracy, while also achieving automated production and reducing production costs.

2. The application of 3D printing technology: 3D printing technology can directly convert designers' design drawings into solid models, thereby making the production of carved aluminum veneer more accurate. 3D printing technology can also achieve rapid customization to meet customers' personalized needs.

3. Innovation in surface treatment technology: Surface treatment technology is a very important part of the manufacturing process of carved aluminum veneer, which directly affects the aesthetics and corrosion resistance of the product. At present, some new surface treatment technologies such as anodizing and spraying are constantly being researched and developed, which can further improve the performance and quality of products.

2、 Development Trends

1. Personalized customization: With the continuous improvement of consumers' demand for personalization, personalized customization of carved aluminum veneer will be increasingly valued. By adopting technologies such as 3D printing, customization can be made according to customer needs to meet their personalized requirements.

2. Intelligent production: With the continuous development of artificial intelligence technology, the intelligent production of carved aluminum veneer will also become a future development trend. By using intelligent devices such as robots, automated production can be achieved, improving production efficiency and accuracy.

3. Green environmental protection: In the current social context of increasing environmental awareness, the green environmental protection of carved aluminum veneer will also become a future development trend. By adopting new materials and technologies, the impact on the environment can be reduced and sustainable development can be achieved.

Carving and carving aluminum veneer, as a new type of building decoration material, has high decorative and artistic value. Through continuous process innovation and research on development trends, it will play a more important role in the future.

Customer service QQ

Customer service QQ