Industry information

Company News

- The new trend of aluminum veneer design and the new proposition of modern home aesthetics!

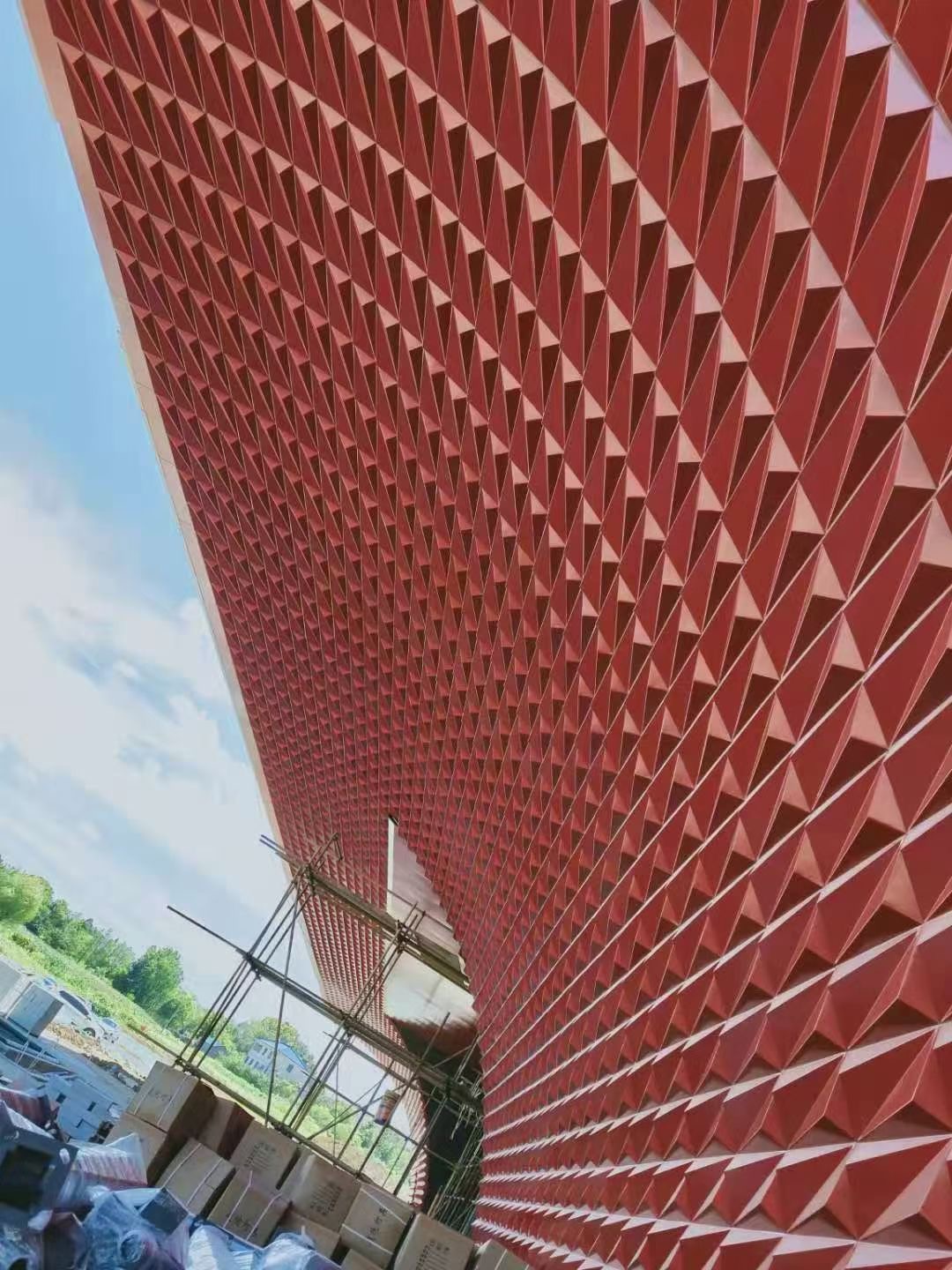

- Punched aluminum veneer, creating a new darling with dual charm of fashion and environmental protection

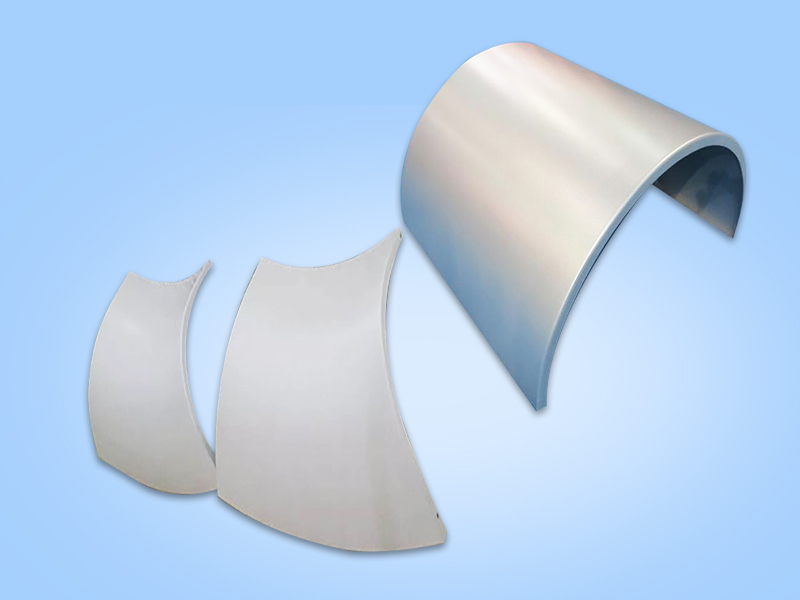

- Aluminum veneer: the beauty of architecture, a new trend of light luxury

- Curtain wall aluminum veneer: a fashionable "coat" in modern architecture

- Display of application cases of aluminum veneer

Industry dynamics

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

- Aluminum Light New Chapter Reveals the Charm and Secrets of Aluminum Veneers in Curtain Walls

- Production technology and patent situation of aluminum veneer

- Punched aluminum veneer: the creative spark of the aluminum world

Frequently asked questions

- What is the production process of aluminum veneer?

- How to improve the practicality of aluminum veneer through innovative applications?

- What is the specific application of aluminum veneer in architectural decoration?

- How to choose a suitable aluminum veneer supplier?

- What is aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

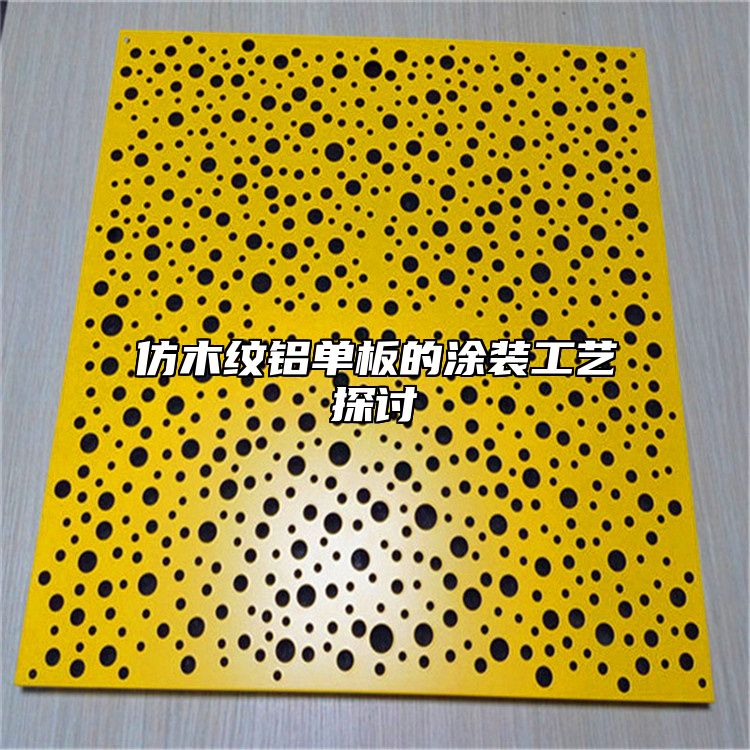

Exploration of Coating Process for Imitation Wood Grain Aluminum Veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-18 11:18:30

- Click:0

As a building material, the appearance effect of imitation wood grain aluminum veneer is one of the important factors to ensure the beauty and practicality of the product. The coating process is one of the key factors affecting the appearance of imitation wood grain aluminum veneer. Below is a detailed introduction to the coating process of imitation wood grain aluminum veneer.

1、 Material characteristics

Before carrying out the coating process of imitation wood grain aluminum veneer, it is necessary to evaluate the material properties. Specifically, it includes the following aspects:

1. Surface treatment: that is, cleaning, polishing, rust removal and other treatments are carried out on the surface of the imitation wood grain aluminum veneer to ensure the coating effect and adhesion.

2. Coating selection: Select the appropriate coating material and color based on the usage environment and requirements of the imitation wood grain aluminum veneer.

3. Coating performance: Testing and evaluating the performance indicators of the selected coating, such as weather resistance, corrosion resistance, hardness, etc.

2、 Painting process flow

When carrying out the coating process of imitation wood grain aluminum veneer, the following steps need to be followed:

1. Surface treatment: Use cleaning agents, polishing machines, and other tools to clean and polish the surface of the imitation wood grain aluminum veneer, removing surface dirt and oxide layers to ensure coating adhesion and aesthetics.

2. Primer coating: After surface treatment, apply primer to the imitation wood grain aluminum veneer to enhance the adhesion and stability between the coating and the substrate.

3. Intermediate coating: After completing the primer coating, apply an intermediate coating to the imitation wood grain aluminum veneer to increase the coating thickness and texture.

4. Topcoat coating: After completing the intermediate coating, apply topcoat to the imitation wood grain aluminum veneer to form the final appearance and color.

5. Baking and curing: After completing the topcoat coating, place the imitation wood grain aluminum veneer in a baking equipment for curing treatment to improve the coating hardness and wear resistance.

3、 Precautions

Before carrying out the coating process of imitation wood grain aluminum veneer, it is necessary to fully understand the characteristics and requirements of the product, and follow relevant specifications and standards for operation.

During the painting process, it is necessary to pay attention to controlling factors such as painting parameters and environmental conditions to ensure that the painting effect meets the design requirements and specified standards.

After the painting is completed, it is necessary to inspect and evaluate the painting effect. If there are any areas that do not meet the requirements, they need to be corrected and adjusted in a timely manner.

4、 Conclusion

The coating process of imitation wood grain aluminum veneer is one of the key links to ensure the appearance and practicality of the product. Through reasonable surface treatment, coating selection, and coating process, high-quality imitation wood grain aluminum veneer coating effect can be achieved, creating a better and more comfortable living environment and social atmosphere for people. In the future development, with the advancement of technology and changes in market demand, the coating process of imitation wood grain aluminum veneer will become more diversified and perfected, bringing people a healthier, more environmentally friendly, and sustainable user experience.

Customer service QQ

Customer service QQ