Industry information

Company News

- hello everyone! Today we will talk about an indispensable element in modern architecture - curtain wall aluminum

- Punched aluminum veneer: a fashionable choice in modern architecture

- Aluminum veneer: the fashionable "green leaf" in modern architecture

- New trend in aluminum veneer design, upgrading home aesthetics

- Aluminum veneer: the 'hidden hero' of modern architecture

Industry dynamics

- Aluminum veneer design, a new chapter in architectural art

- Aluminum veneer curtain wall, the new darling of architectural art

- Aluminum veneer design, a new chapter in architectural aesthetics

- Aluminum veneer design, creating a new trend of personalized space

- Aluminum veneer curtain wall, a new chapter in architectural aesthetics

Frequently asked questions

- What is aluminum veneer?

- What is the specific application of aluminum veneer in architectural decoration?

- What is the market outlook and development trend of aluminum veneer?

- What is the production process of aluminum veneer?

- What are the precautions for the design and installation of aluminum veneer curtain walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

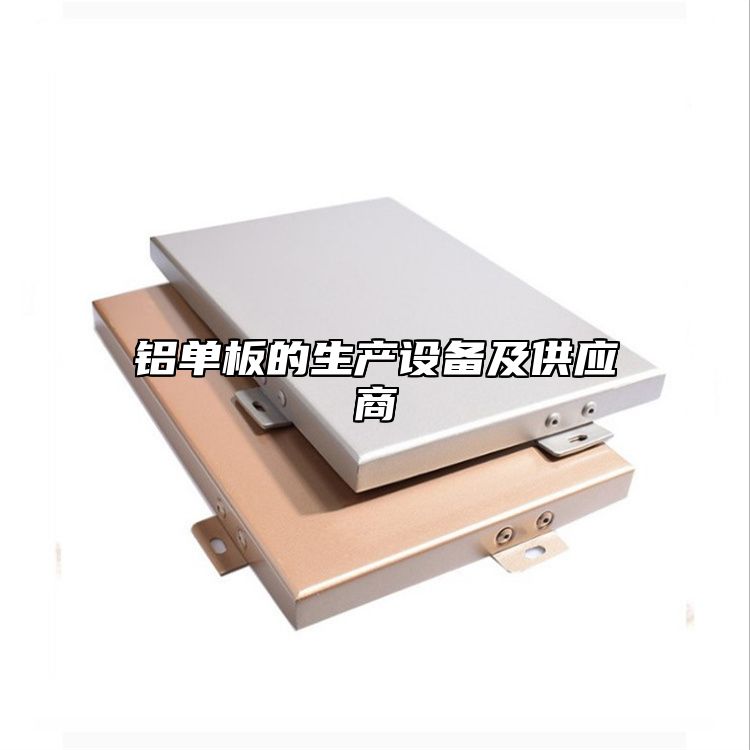

Production equipment and suppliers of aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-16 18:19:16

- Click:0

Production equipment and suppliers of aluminum veneer

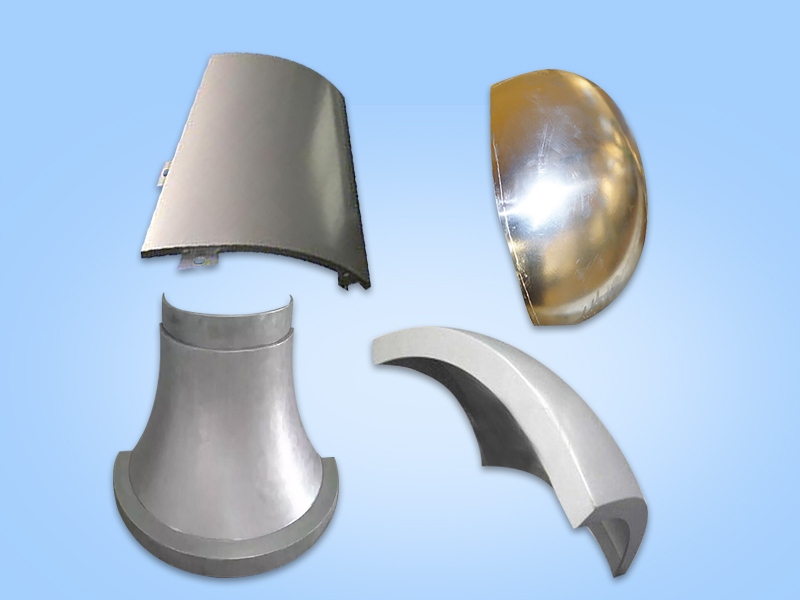

Abstract: Aluminum veneer, as a widely used material in the construction industry, its production equipment and suppliers have a significant impact on product quality and market competitiveness. This article will provide a detailed explanation of the production equipment and suppliers of aluminum veneer from four aspects.

1、 Selection of production equipment

1. Injection molding equipment: Injection molding equipment is a crucial part of the production process of aluminum veneer. It achieves the formation of aluminum veneer by injecting melted aluminum material into the mold. The main injection molding equipment suppliers in the current market include Company A, Company B, and Company C. By communicating with users about their needs, these manufacturers are able to provide customized equipment and have excellent after-sales service.

2. Coating equipment: Surface coating of aluminum veneer is an important process to protect aluminum from oxidation and corrosion. High quality coating equipment can ensure uniform coating, strong adhesion, and weather resistance. Among painting equipment suppliers, D company, E company, and F company are well-known choices in the market. They provide various specifications of spraying equipment and drying equipment to meet the production needs of different manufacturers.

3. Bending equipment: Aluminum veneer usually needs to be bent to meet the needs of different building structures. The performance of bending equipment directly affects the quality and processing efficiency of products. G Company, H Company, and I Company have a certain market share in the field of bending equipment. They provide high-precision and stable bending equipment and continuously innovate and upgrade their technology to meet the development needs of the market.

2、 Supplier selection

1. Quality assurance: Choosing the right supplier is crucial for ensuring the quality of aluminum veneer. Firstly, suppliers should have excellent manufacturing processes and quality control systems to ensure product stability and consistency. Secondly, suppliers should possess comprehensive supply chain management capabilities to ensure timely supply of raw materials and inventory control. Finally, suppliers should have flexible production capabilities to meet the rapidly changing market demands.

2. Collaboration experience: Supplier collaboration experience is also an important factor in selection. Collaborating with experienced suppliers can provide better technical support and solutions. Meanwhile, the cooperation experience of suppliers can also reflect their competitiveness and reputation in the market. By communicating and comparing with multiple suppliers, selecting suppliers with good cooperation experience can reduce supply chain risks and improve product quality.

3. After sales service: High quality after-sales service is one of the important considerations when choosing a supplier. Suppliers should provide timely technical support and be able to respond quickly and solve problems. In addition, suppliers should provide training and maintenance services to help users better use and maintain equipment. It is wise to weigh the quality of pre-sales and after-sales services comprehensively and choose a supplier that provides comprehensive services.

3、 Industry Development Trends

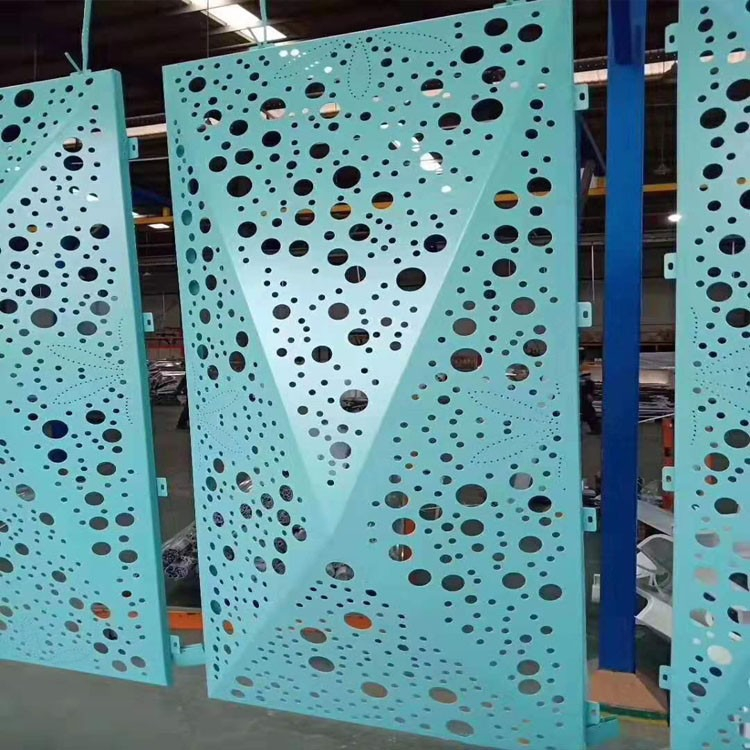

1. Technological innovation: With the increasing demand for aluminum veneer in the construction industry, production equipment and suppliers are also constantly innovating in technology. For example, some suppliers have introduced automated production lines to improve production efficiency; Some suppliers have also developed environmentally friendly coatings and new bending equipment to meet the market's demand for environmental performance and diversity.

2. Market competition: With the expansion of the aluminum veneer market, competition between production equipment and suppliers is becoming increasingly fierce. Suppliers compete for market share by providing higher quality products and services, reducing costs, and strengthening brand influence. This competition will drive the development and innovation of the industry, bringing more choices and opportunities.

3. International Cooperation: The internationalization level of the aluminum veneer industry is constantly improving, and production equipment and suppliers are actively engaging in international cooperation. Through technical exchanges and cooperation with advanced foreign enterprises, domestic manufacturers can introduce more advanced equipment and processes, enhance their competitiveness, and expand overseas markets.

4、 Future Development Trends

1. Intelligent development: With the rapid development of artificial intelligence technology, intelligent production has become a future trend. Production equipment and suppliers will face more intelligent demands, such as automated production lines, machine learning, etc. Suppliers need to continuously improve their technological level to meet the needs of intelligent production.

2. Green environmental protection: The increasing awareness of environmental protection has made green environmental protection an important development direction for the aluminum veneer industry. Production equipment and suppliers should strengthen the research and development of new environmentally friendly materials and processes to provide more environmentally friendly products and solutions.

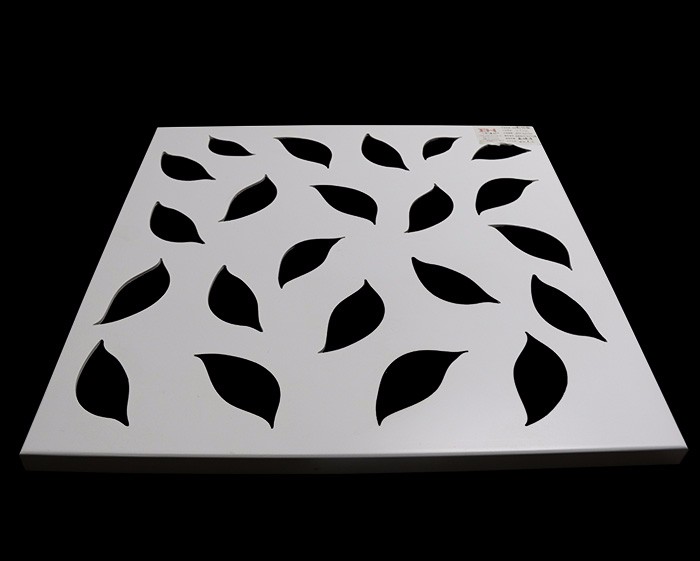

3. Diversified demand: Consumers' demand for aluminum veneer products is becoming increasingly diversified, and production equipment and suppliers need to face personalized needs in different specifications, colors, surface treatments, and other aspects. Suppliers should have flexible production and innovation capabilities to meet the diverse demands of the market.

5、 Summary

Through a detailed explanation of the production equipment and suppliers for aluminum veneer in this article, we have come to understand the importance of selecting production equipment and suppliers for the quality and competitiveness of aluminum veneer. At the same time, with the analysis of the industry's development dynamics and future trends, we can foresee that intelligence, green environmental protection, and diversified demands will become important development directions for the aluminum veneer industry. When choosing production equipment and suppliers, we should consider their technical strength, cooperation experience, and after-sales service to meet market demand and improve product quality.

- previous page:Design and installation of aluminum veneer curtain wall

- Next page:Transportation and storage of aluminum veneer

Customer service QQ

Customer service QQ