Industry information

Company News

- Aluminum veneer: not just decoration, but also the soul of architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum veneer: the elegant choice for modern architecture?

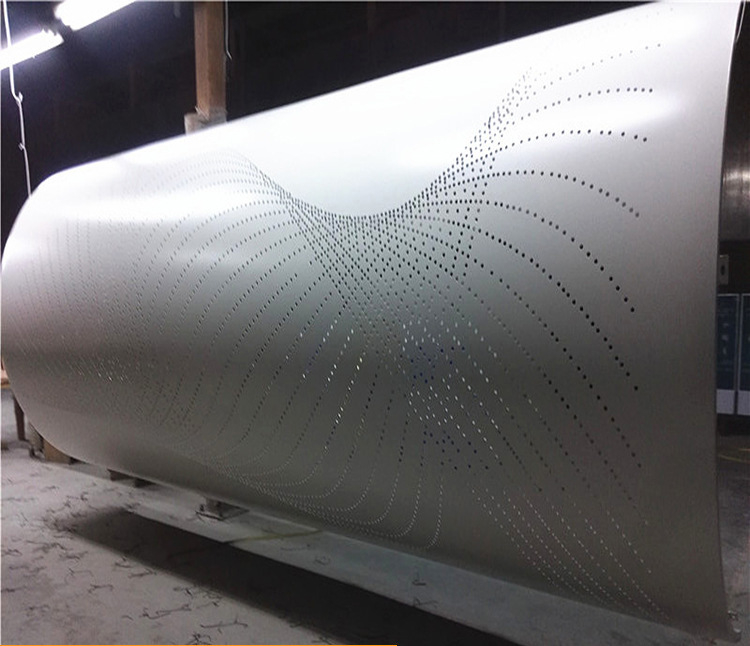

- Punched aluminum veneer: a fashionable choice in modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall, the "gorgeous coat" of modern architecture

- Punched aluminum veneer: the new darling of creative space

- Aluminum veneer design new trend: the beauty of lightness, all under control

Frequently asked questions

- What are the precautions for the design and installation of aluminum veneer curtain walls?

- What is the specific application of aluminum veneer in architectural decoration?

- What is the production process of aluminum veneer?

- How to choose a suitable aluminum veneer supplier?

- How to improve the practicality of aluminum veneer through innovative applications?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

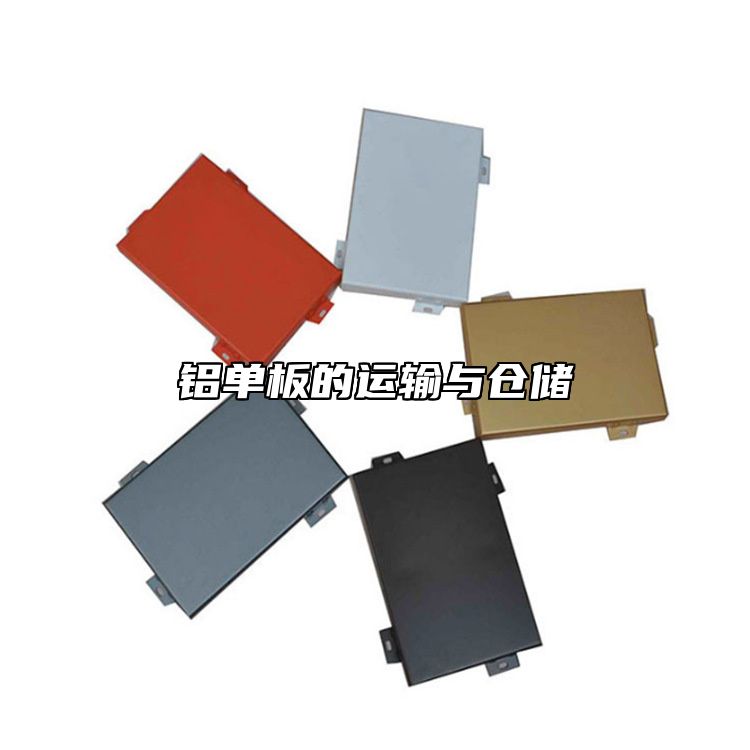

Transportation and storage of aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-17 16:08:50

- Click:0

Summary:

Aluminum veneer, as a commonly used building material, plays a role in beautifying and protecting buildings. During transportation and storage, we need to pay attention to protecting the quality and safety of aluminum veneer. This article will provide a detailed explanation of the transportation and storage of aluminum veneer from four aspects, including packaging requirements, transportation methods, storage environment, and management measures.

1、 Packaging requirements

1. Appropriate packaging materials:

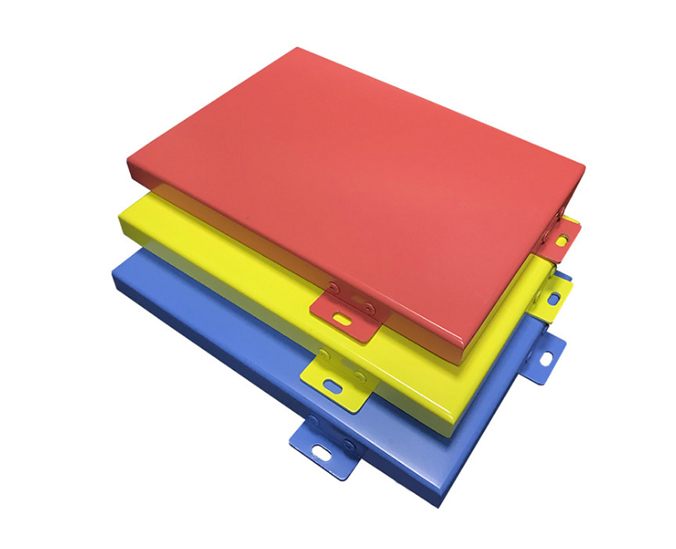

Aluminum veneer is susceptible to external impact and compression during transportation, therefore packaging materials with certain protective properties must be used. Common packaging materials include foamed plastics, boards and cartons.

2. Reasonable packaging method:

When packing, the appropriate packaging method should be selected according to the size and weight of the aluminum veneer. Stacked packaging or integral packaging can be used to ensure that the aluminum veneer will not deform or be damaged.

3. Clear identification:

Each packaging box should be clearly labeled with information, including the specifications, quantity, and weight of the aluminum veneer. This can facilitate the warehouse administrator's acceptance and storage.

2、 Transportation mode

1. Land transportation:

The land transportation of aluminum veneer is a common mode of transportation, which can be carried out by trucks, trains, or containers. When choosing transportation vehicles, the weight and size of the goods should be considered, and it should be ensured that there are no collisions or squeezes during transportation.

2. Sea freight:

For large quantities of aluminum veneer, sea freight is an economical, safe, and reliable transportation method. During the sea transportation process, it is necessary to choose suitable containers and strengthen waterproof and moisture-proof measures to avoid damage to aluminum veneers from moisture and seawater.

3. Air freight:

If urgent transportation of aluminum veneer is required, air freight can be chosen. Air freight is fast, but the cost is high. It is necessary to pay attention to the firmness of the packaging to prevent the goods from shaking or sliding during transportation.

3、 Storage environment

1. Temperature and humidity control:

Aluminum veneer needs to maintain appropriate temperature and humidity during storage to avoid problems such as oxidation and deformation. The warehouse should be equipped with constant temperature and humidity equipment to control environmental conditions.

2. Ventilation and dust prevention:

The warehouse should have good ventilation facilities to ensure air circulation. At the same time, dust prevention measures should be taken to avoid the impact of dust on aluminum veneer.

3. Lighting control:

Aluminum veneer can have a certain impact on direct sunlight and is prone to surface discoloration or quality loss. Therefore, the lighting inside the warehouse should be controlled at an appropriate level as much as possible.

4、 Management measures

1. Inventory management:

The warehouse administrator needs to establish a scientific inventory management system to record and monitor the inbound and outbound status of aluminum veneer. Timely adjust inventory to ensure the turnover rate of goods.

2. Quality control:

During the transportation and storage of aluminum veneer, necessary quality inspections and sampling tests are conducted to ensure that the products meet the standard requirements, and timely measures are taken to deal with non-conforming products.

3. Security protection:

The warehouse should strengthen security management to ensure that aluminum veneers are not stolen or damaged. Install monitoring equipment, control entrances and exits, and ensure the safety of goods.

5、 Summary:

The transportation and storage of aluminum veneer are important links to ensure product quality and safety. Reasonable packaging requirements, selection of appropriate transportation methods, maintenance of a good storage environment, and scientific management measures can all improve the transportation efficiency and protection level of aluminum veneer. In order to ensure the high-quality transmission of aluminum veneer throughout the entire supply chain, we need to strengthen the management and monitoring of transportation and warehousing processes, and continuously improve and optimize them.

- previous page:Production equipment and suppliers of aluminum veneer

- Next page:The production process flow of aluminum veneer

Customer service QQ

Customer service QQ