Industry information

Company News

- Aluminum veneer, the "lightweight" choice in architectural aesthetics

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: the new darling of architectural aesthetics. How much do you know about it?

- Can your building withstand the fashionable charm of perforated aluminum veneer?

- The charm of aluminum veneer: not just the material, but also the art

Industry dynamics

- Unveiling the Charm of Aluminum Veneer: The 'Silver Fashion' of Modern Architecture

- Exploring perforated aluminum veneer: the new aesthetic favorite of modern architecture

- New Trend of Aluminum Veneer: Shaped Aluminum Veneer Leads a New Style of Architectural Aesthetics

- Unique design stone patterned aluminum veneer

- Production technology and patent situation of aluminum veneer

Frequently asked questions

- How to choose a suitable aluminum veneer supplier?

- What is the market outlook and development trend of aluminum veneer?

- What is the specific application of aluminum veneer in architectural decoration?

- What is the environmental performance of aluminum veneer?

- What are the advantages of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production technology and patent situation of aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 14, 2025 15:14:16

- Click:0

abstract

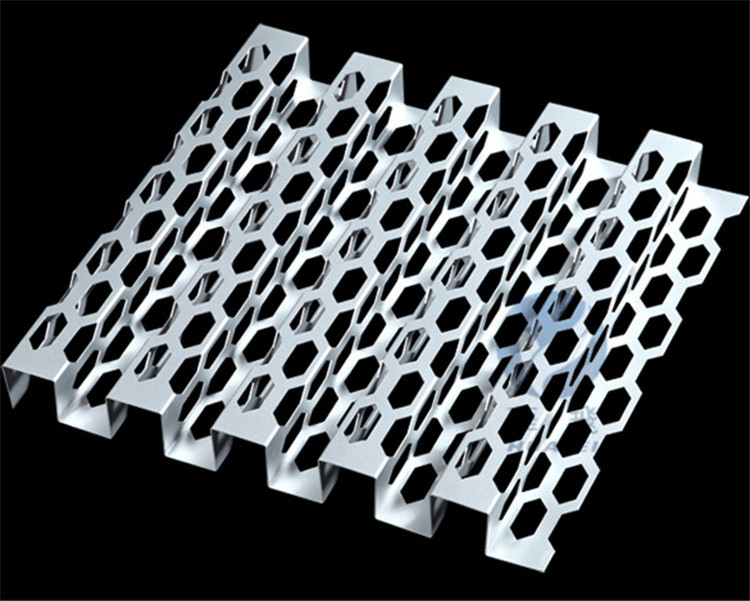

With the development of technology, aluminum veneer, as a new type of material, has been widely used in the field of architectural decoration. This article will provide a detailed explanation of the four aspects of aluminum veneer production, namely production process, material selection, mold design, and patent situation.

1、 Production process

The production process mainly includes aluminum veneer embossing, shearing processing, coating treatment, and forming technology. Among them, the embossing process of aluminum veneer is an important process for forming the texture of aluminum veneer, which achieves different texture effects by applying different pressing forces to the aluminum plate and using different embossing molds. The cutting processing technology is mainly used for cutting, slicing, chamfering and other processing of fixed length aluminum plates. The coating treatment process involves spraying and oxidation treatment on the surface of aluminum plates to enhance their hardness and corrosion resistance. Finally, the forming process refers to the bending, splicing, welding, and other forming processes of the processed aluminum veneer according to the design sample.

At present, the production process of aluminum veneer is gradually developing towards digitalization and intelligence, and the processing accuracy of various production processes is also constantly improving. At the same time, some new aluminum plate processing technologies are also applied in the aluminum plate production process, such as laser cutting and wire electrical discharge cutting.

2、 Material selection

The main component of aluminum veneer is aluminum alloy, and some auxiliary materials need to be added. Aluminum alloy is widely used in the field of architectural decoration due to its advantages such as lightweight, corrosion resistance, and easy processing. Auxiliary materials include oxide paint, coatings, adhesives, etc., which play an important role in the surface treatment and processing of aluminum plates.

At present, there are some new environmentally friendly aluminum materials on the market, which have better characteristics such as wind pressure resistance, sound insulation, and corrosion resistance compared to traditional aluminum plates. At the same time, in terms of aluminum plate material selection, there is an increasing tendency to choose aluminum plate materials that meet national environmental standards and are environmentally friendly.

3、 Design mold

Designing molds is a crucial step in the production of aluminum veneer. The quality of mold design directly affects the surface pattern and aesthetics of aluminum plates. At present, there are some advanced CNC mold making equipment on the market that can quickly produce high-quality design molds according to customer requirements.

At the same time, researchers are constantly exploring new design mold materials and manufacturing processes. For example, by using 3D printing technology, multiple parts can be designed into an integrated and complete structure, improving the accuracy and stability of the mold.

4、 Patent situation

With the continuous expansion of the aluminum veneer market, more and more companies are applying for patents in order to protect their intellectual property rights. In the production of aluminum veneer, it mainly involves design patents and utility model patents. Design patents mainly protect the patterns and structures on the surface of aluminum plates, while utility model patents protect the production process and application scenarios of aluminum plates.

At present, many domestic and foreign enterprises and individuals have obtained patents related to aluminum veneer, including some very valuable invention patents and utility model patents. The emergence of these patents has played an important role in promoting the development and innovation of the aluminum veneer industry.

5、 Summary

The production technology and patent situation of aluminum veneer are important guarantees for the continuous development of the aluminum veneer industry. With the advancement of technology and market demand, the production technology of aluminum veneer is gradually upgrading and improving. At the same time, the number of patents related to aluminum veneer is constantly increasing, providing more innovation space for enterprises while also protecting their intellectual property and core competitiveness. I believe that in the near future, the aluminum veneer industry will become increasingly mature and perfect.

- previous page:The production process flow of aluminum veneer

- Next page:Production cost and market price of aluminum veneer

Customer service QQ

Customer service QQ