Industry information

Company News

- Aluminum veneer design is a new trend, a fashionable home choice!

- Aluminum veneer, the "lightweight" choice in architectural aesthetics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Market prospects and investment suggestions for aluminum veneer

- Aluminum veneer design, a fashionable choice for modern architecture

Industry dynamics

- Aluminum veneer curtain wall, creating a fashionable exterior for modern architecture

- Punched aluminum veneer: the new darling of creative space

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer and green building

- Aluminum veneer is the new trend, with infinite possibilities in design!

Frequently asked questions

- What are the precautions for the design and installation of aluminum veneer curtain walls?

- What is the environmental performance of aluminum veneer?

- What is the specific application of aluminum veneer in architectural decoration?

- How to improve the practicality of aluminum veneer through innovative applications?

- How to choose a suitable aluminum veneer supplier?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Processing and installation technology of aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-18 17:52:42

- Click:0

1、 Processing technology of aluminum veneer

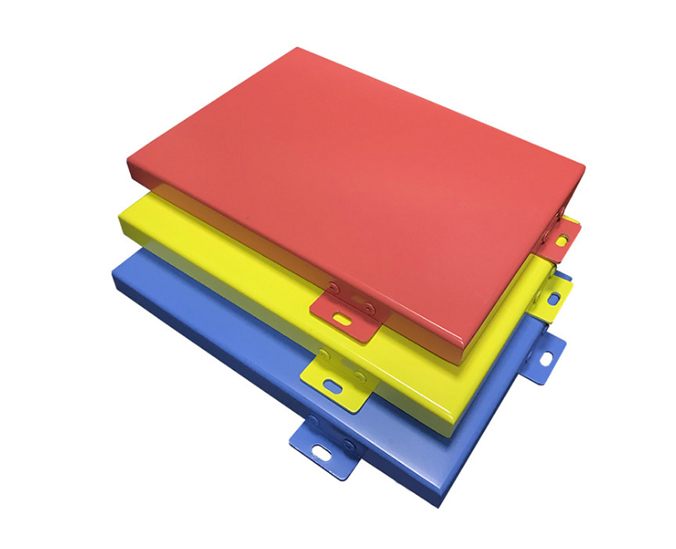

Aluminum veneer has the advantages of lightweight, fire resistance, and corrosion resistance, and is widely used in exterior wall decoration of buildings. However, the processing technology of aluminum veneer is also an important factor affecting its quality and installation effect. Introduce the processing technology of aluminum veneer from the following aspects:1. Cutting process

Aluminum veneer can be processed by mechanical cutting or thermal cutting, where mechanical cutting is suitable for some simple patterns or curved shapes, while thermal cutting is suitable for complex patterns or curved shapes. During the cutting process, attention should be paid to the selection of cutting tools and the sharpness of the cutting edge to ensure smooth cutting edges.2. Bending process

Aluminum veneer can be bent manually or mechanically to achieve different curved shapes. When manually bending, it is necessary to use appropriate tools and force, and avoid mechanical damage to the aluminum veneer. Mechanical bending can be carried out with the help of CNC equipment to ensure bending accuracy and efficiency.3. Drilling process

Drilling is required during the installation process, and the position and size of the drill holes should be accurate and precise. The drilling of aluminum veneer can be carried out using drill bits or laser drills, and laser drilling can ensure accuracy and efficiency.2、 Coating process of aluminum veneer

The coating process of aluminum veneer can also affect its quality and durability. Before painting, it is necessary to perform surface treatment on the aluminum plate to remove dirt and oxides, and then select and apply coating materials. The following is the coating process for aluminum veneer:1. Surface treatment

Surface treatment mainly includes steps such as decontamination, rust removal, acid washing, and anodizing. Acid washing and anodizing can improve the corrosion resistance and weather resistance of aluminum veneer.2. Coating material selection

Coating materials are generally selected from materials such as polyester, fluorocarbon, polyurethane, and silicone. The characteristics and applicability of different coatings vary, and the selection needs to be based on the actual situation.3. Painting construction

Coating construction requires attention to factors such as spray thickness, coating uniformity, and drying time. During the painting process, it is necessary to ensure stable environmental temperature and humidity, and strictly follow the construction specifications for operation.3、 Connection method of aluminum veneer

The connection method of aluminum veneer determines its installation effect and stability. The commonly used connection methods for aluminum veneer are as follows:1. Riveted connection

Rivet connection is suitable for connecting aluminum veneers and aluminum profiles, using bolts and rivets for connection, and has the characteristics of strong structure and not easy to loosen.2. Dry hanging connection

Dry hanging connection is to hang aluminum veneer on the supporting structure and connect it with hanging parts and buckles. Dry hanging connections have the characteristics of easy installation and maintenance, and are suitable for large-scale exterior wall decoration of buildings.3. Spot welding connection

Spot welding connection is suitable for connecting aluminum veneer and steel structure, using spot welding machine for welding. Spot welding connection has the characteristics of small welding points, beautiful appearance, and high connection strength.4、 Precautions for installation of aluminum veneer

The installation of aluminum veneer requires attention to the following aspects to ensure installation quality and effectiveness:1. Construction design

When designing the supporting structure, factors such as the weight, wind pressure, and seismic resistance of the installed aluminum veneer need to be considered. At the same time, it is necessary to determine the connection method and installation location based on the actual situation.2. Construction specifications

When installing aluminum veneer, it is necessary to strictly follow the design and construction specifications, and use professional decoration companies or technical personnel for the operation.3. Safety protection

Attention should be paid to safety protection during the installation of aluminum veneer, especially when working at heights, safety ropes and other protective equipment should be equipped to ensure the safety of construction personnel.4. Maintenance and upkeep

After installation, regular maintenance is required for the aluminum veneer, cleaning the surface dirt and damaged coating areas, and promptly repairing and replacing them.- previous page:Production cost and market price of aluminum veneer

- Next page:Surface treatment technology of aluminum veneer

Customer service QQ

Customer service QQ