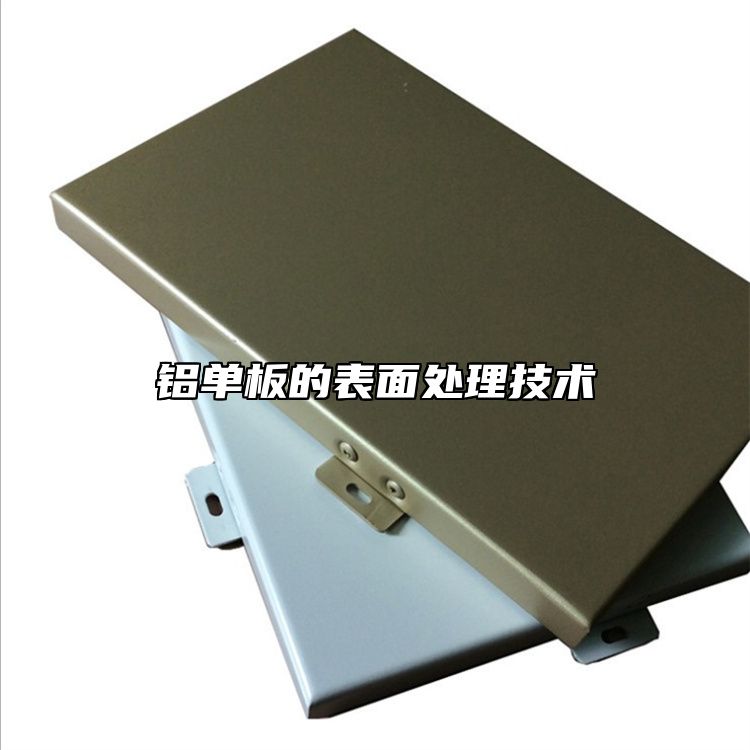

1、 The significance of surface treatment technology for aluminum veneer

Aluminum veneer is a widely used material in the construction industry, and the quality of its surface treatment technology directly affects the service life and appearance of aluminum veneer. Therefore, the research and improvement of surface treatment technology for aluminum veneer are particularly important. Firstly, excellent surface treatment techniques can enhance the corrosion resistance of aluminum veneer, preventing rusting and oxidation. At the same time, it can also improve the wear resistance and hardness of aluminum veneer, enhance its load-bearing capacity and mechanical strength, making aluminum veneer more solid and durable during use. Secondly, aluminum veneer, as a building decoration material, also plays an important role in the appearance effect. The continuous improvement of surface treatment technology can bring better visual and tactile effects to aluminum veneer, making buildings more beautiful and fashionable.

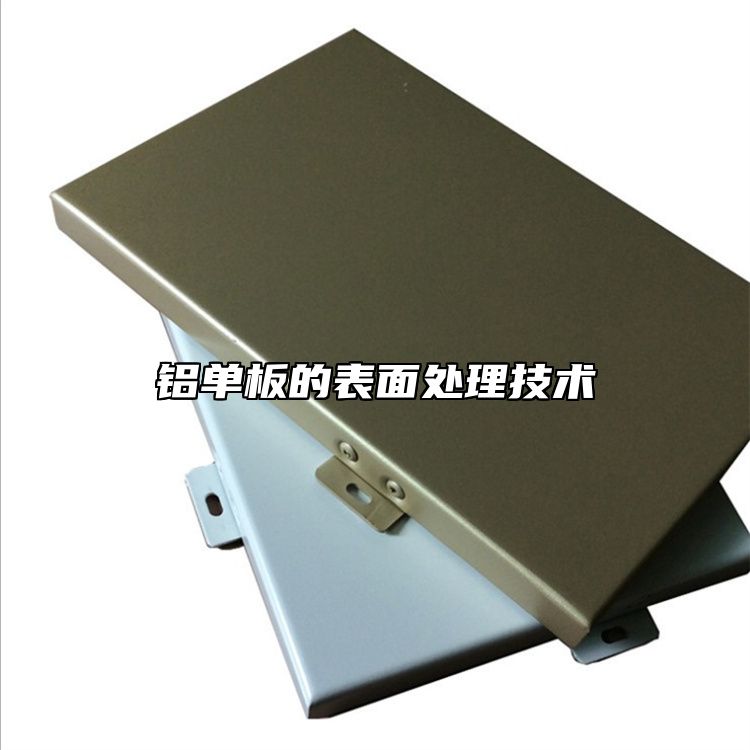

2、 Types of surface treatment technologies for aluminum veneer

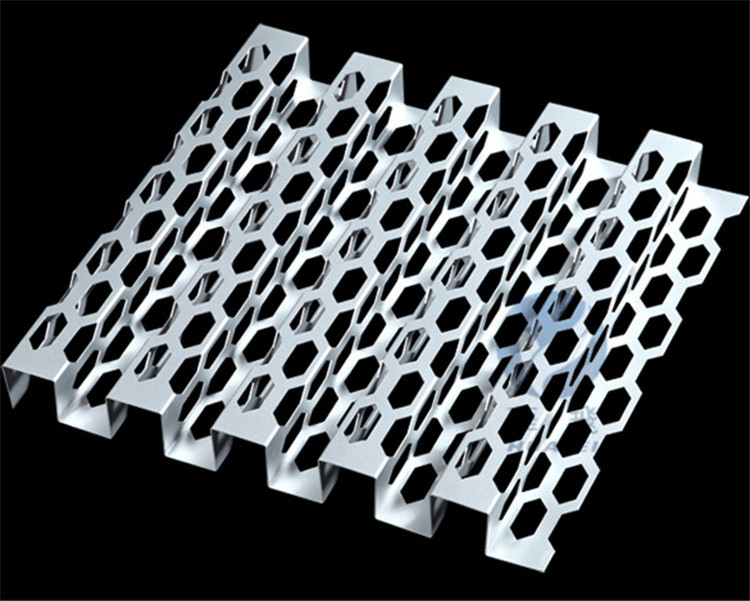

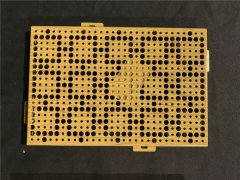

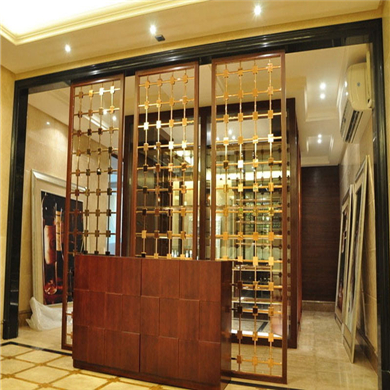

The surface treatment technology of aluminum veneer can usually be divided into various methods such as mechanical scratching, laser drilling, heat transfer printing, spraying, and so on. The method of mechanical scratching is to use mechanical cutting or cold rolling to form patterns of a certain depth. Laser drilling, on the other hand, involves leaving small, well shaped holes directly on the surface of a material using a laser beam. Heat transfer printing is the process of firmly bonding printed film onto aluminum veneer through high temperature and high pressure. Spraying is the use of a spray gun to apply pigments onto the surface of aluminum veneer, forming a uniform and aesthetically pleasing surface coating.

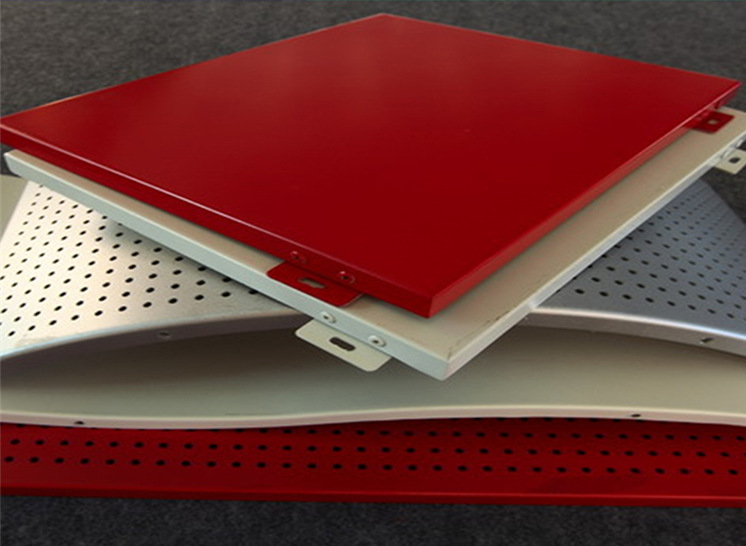

3、 Application of surface treatment technology for aluminum veneer

The surface treatment technology of aluminum veneer has a wide range of applications in the construction industry. Among them, the surface treatment technology of mechanical scratches can make aluminum plates more textured and aesthetically pleasing, and is commonly used in the production of decorative materials such as indoor ceilings and walls. Laser drilling can provide natural lighting for buildings and is often used for indoor screens, partition walls, and other occasions. Heat transfer printing technology can achieve personalized pattern customization and is commonly used in various large shopping malls, hotels, restaurants, high-end office buildings, and other high growth economic areas. Spraying technology can achieve anti-corrosion and rust prevention functions, and is commonly used in building materials such as outdoor canopies and roofs.

4、 Research direction of surface treatment technology for aluminum veneer

The research directions of surface treatment technology for aluminum veneer mainly include the following aspects: firstly, improving the compressive and wear resistance of aluminum veneer, reducing the occurrence of scratches and damage during use, and thus extending the service life of aluminum veneer; Secondly, explore new surface treatment technologies, such as chemical reaction based surface treatment techniques, to improve the surface hardness and corrosion resistance of aluminum veneer; Thirdly, further improve the automation level of aluminum veneer surface treatment technology, achieve automatic processing of aluminum veneer surface through advanced intelligent equipment and robots, and improve efficiency and quality level; Fourthly, explore surface treatment technologies for aluminum veneer based on environmental protection, energy conservation, and sustainable development to reduce environmental pollution and improve the green index of buildings.

5、 Summary

As an indispensable material in the construction industry, the surface treatment technology of aluminum veneer plays a crucial role in the appearance and service life of buildings. In the future, with the continuous development and progress of technology, the surface treatment technology of aluminum veneer will also continue to innovate and break through, bringing better surface treatment effects and quality assurance to the construction industry.

Customer service QQ

Customer service QQ