Industry information

Company News

- Punched aluminum veneer: a new trend in aluminum art and a new darling of modern architecture

- Aluminum veneer curtain wall, the new garment of architectural art

- Aluminum veneer customization, creating an artistic journey of personalized space

- Art in Holes - Exploring the Beauty of Punched Aluminum Veneers

- Aluminum veneer design, infinite creative space art!

Industry dynamics

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer: the fashionable outerwear of modern architecture

- Punched aluminum veneer: the fashionable new favorite of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What are the production equipment for aluminum veneer and what is their approximate price?

- How to choose a suitable aluminum veneer supplier?

- What is the specific application of aluminum veneer in architectural decoration?

- How to improve the practicality of aluminum veneer through innovative applications?

- What is the market outlook and development trend of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

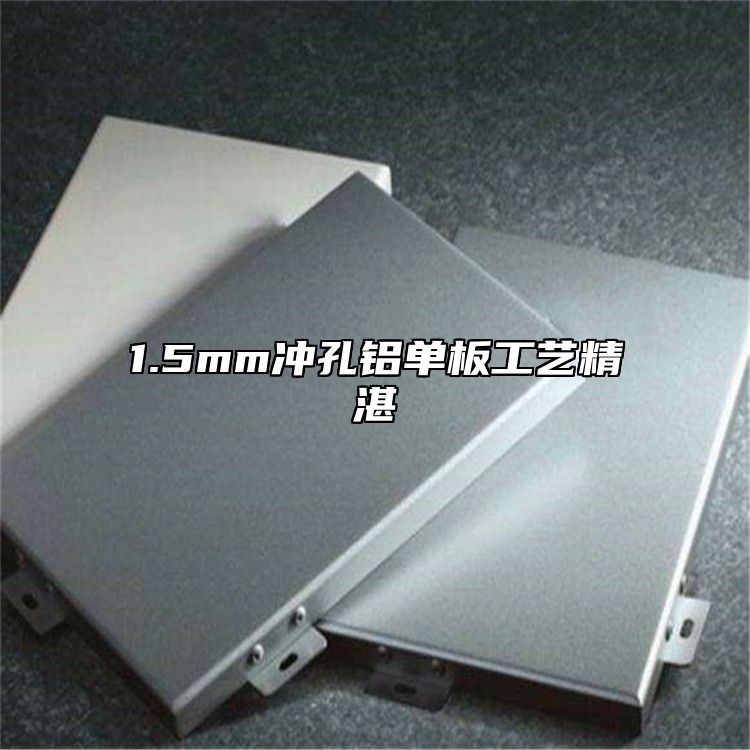

Exquisite craftsmanship of 1.5mm punched aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 18:57:04

- Click:0

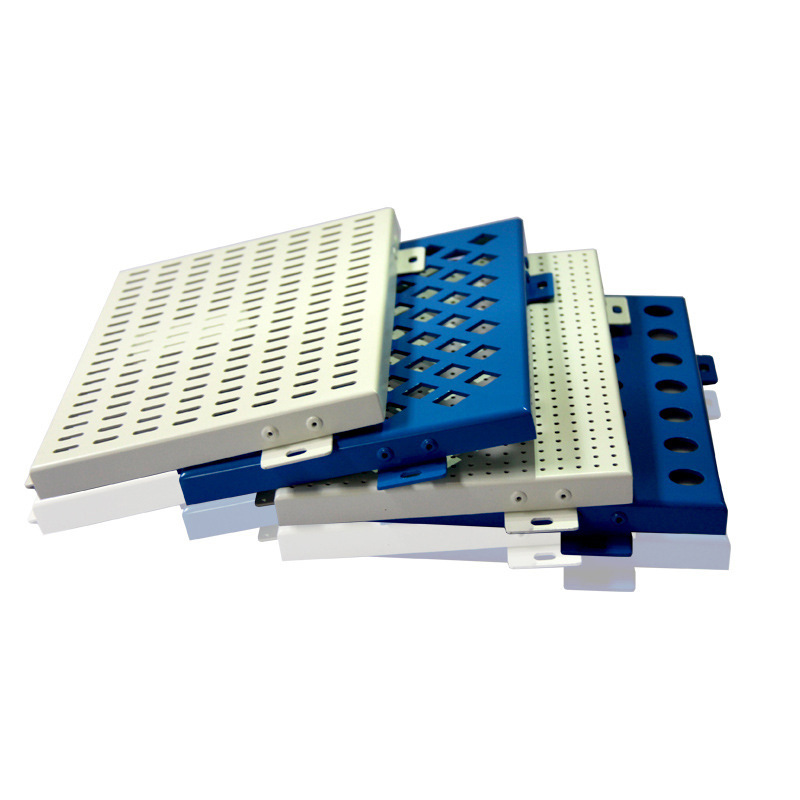

As a commonly used building decoration material, 1.5mm perforated aluminum veneer not only has a beautiful appearance, but also has good performance and stable service life. This cannot be achieved without its exquisite craftsmanship. This article will introduce the exquisite craftsmanship of 1.5mm punched aluminum veneer from multiple aspects.

1、 Selection of raw materials

The main raw material for 1.5mm punched aluminum veneer is aluminum alloy sheet, and high-quality raw materials are an important foundation for ensuring product quality. Aluminum veneer manufacturers must strictly control the selection of raw materials to ensure that they meet national standards and requirements.

2、 Advanced production technology

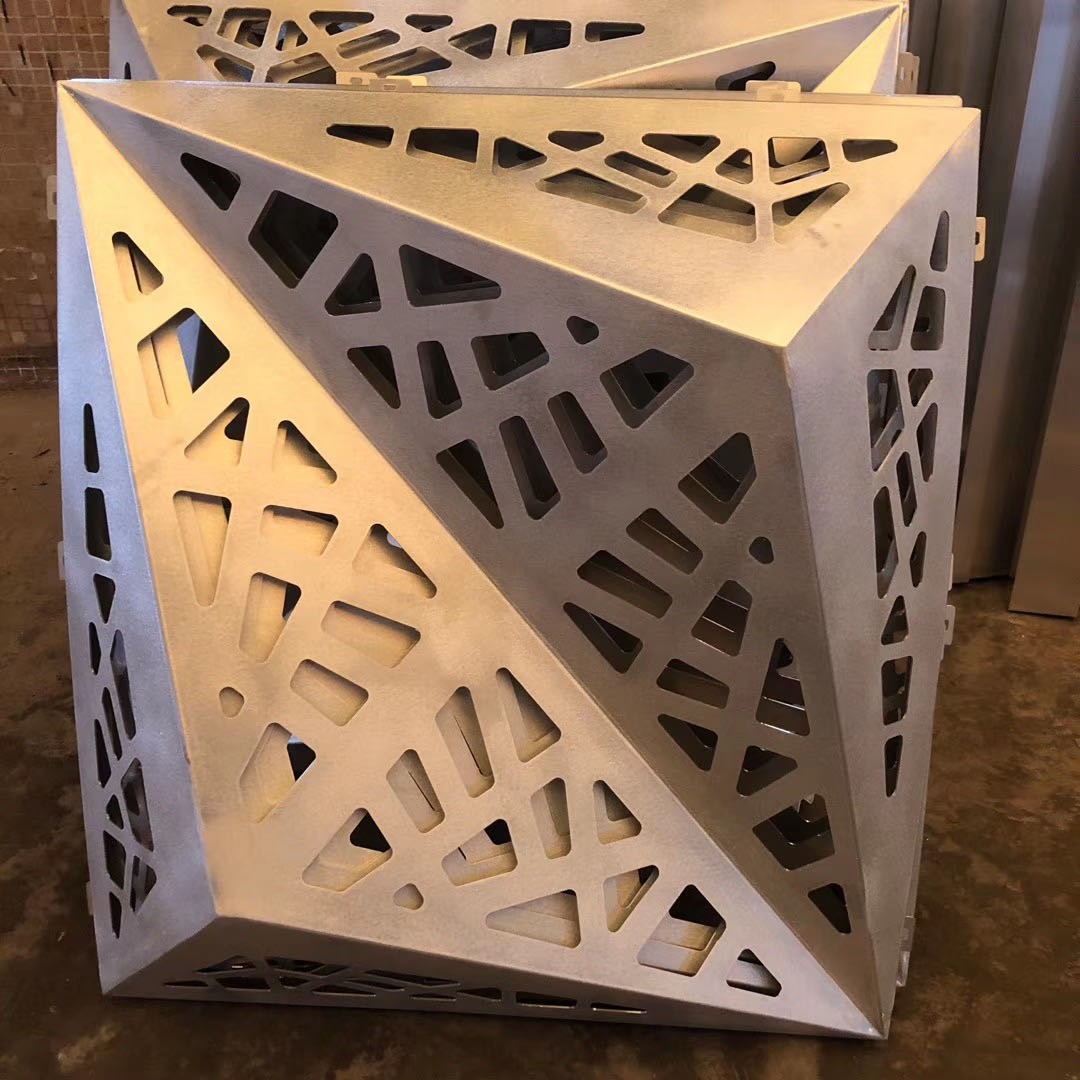

The production process of 1.5mm punched aluminum veneer is very complex and requires multiple steps to complete. This includes cutting, bending, punching, welding and other processes. Aluminum veneer manufacturers need to adopt advanced production equipment and technology to ensure that every link can meet high quality requirements.

3、 Strict quality control

The quality control of 1.5mm punched aluminum veneer is very important and requires strict monitoring and testing throughout the entire production process. Aluminum veneer manufacturers should establish a comprehensive quality management system, conducting detailed inspections and tests at every stage to ensure stable and reliable product quality.

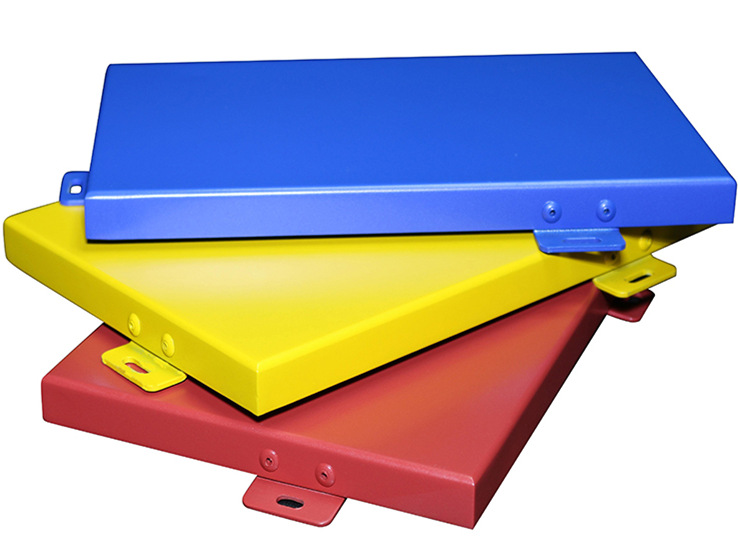

4、 Fine surface treatment

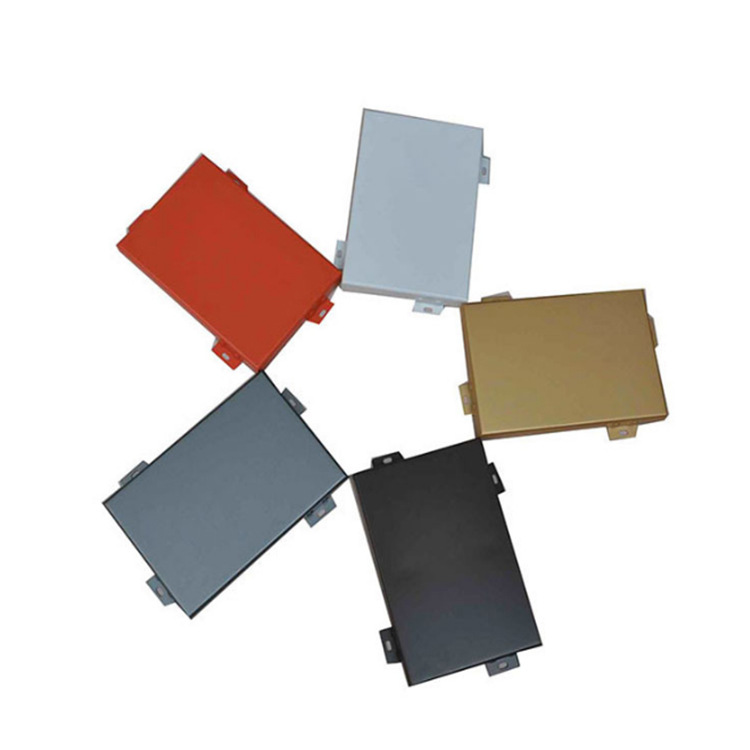

The surface treatment of 1.5mm punched aluminum veneer is also an important manifestation of exquisite craftsmanship. Usually, aluminum veneer manufacturers will perform surface treatments such as spraying and anodizing on aluminum veneer to improve its corrosion resistance and decorative effect. These processing procedures require very precise operations and strict control to ensure that the quality of surface treatment reaches its optimal state.

5、 Innovative design concept

In addition to exquisite craftsmanship, 1.5mm punched aluminum veneer also requires innovative design concepts. Aluminum veneer manufacturers should continuously introduce new design styles and product styles based on market demand and customer needs to meet customers' personalized needs. Innovative design concepts can also enhance the added value and competitiveness of products.

6、 Conclusion

The exquisite craftsmanship of 1.5mm punched aluminum veneer is an important guarantee for its high quality and stability. Aluminum veneer manufacturers should pay attention to the selection of raw materials, advanced production processes, strict quality control, fine surface treatment, and innovative design concepts to ensure that the quality and service level of their products remain at the forefront of the industry.

Customer service QQ

Customer service QQ