Industry information

Company News

- Aluminum veneer design, unlimited creative space

- Aluminum veneer: the 'invisible master' of the construction industry

- Punched aluminum veneer: a fashionable "little freshness" in the world of aluminum materials

- Aluminum veneer: the green choice for modern architecture

- The Fashion Revolution of Aluminum Veneer: The Glorious Turn of Materials

Industry dynamics

- Application of perforated roller coated aluminum veneer in architectural decoration

- Punched aluminum veneer: a fashionable choice for modern architecture

- Curtain wall aluminum veneer: a window of charm for modern architectural art

- Punched aluminum veneer: creating a new style of modern architecture

- The new favorite of aluminum veneer - the unique charm of punched aluminum veneer

Frequently asked questions

- What are the advantages of aluminum veneer?

- What is aluminum veneer?

- What is the production process of aluminum veneer?

- What is the market outlook and development trend of aluminum veneer?

- What are the production equipment for aluminum veneer and what is their approximate price?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

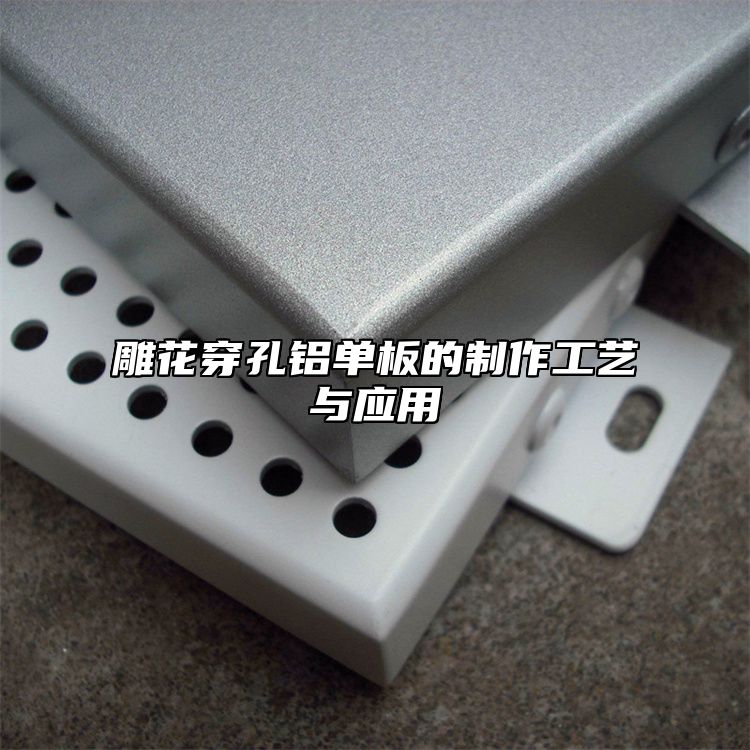

The production process and application of carved perforated aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 17, 2025 06:00:26

- Click:0

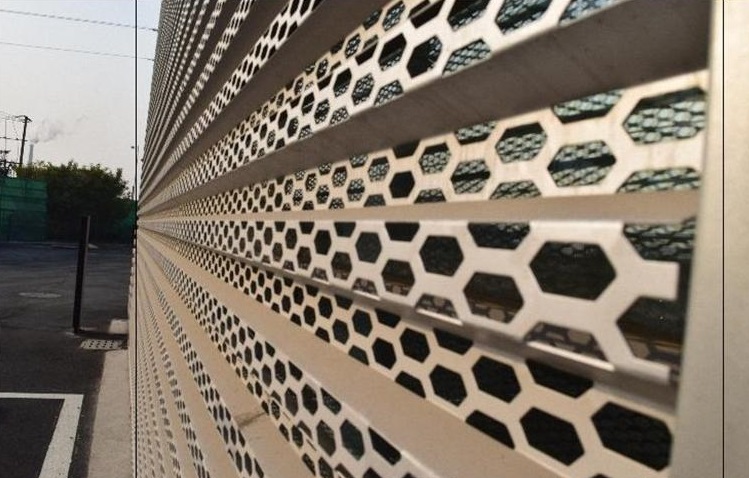

Carved perforated aluminum veneer is a new type of building material with unique manufacturing techniques and decorative effects. The following will provide a detailed introduction to its manufacturing process and application.

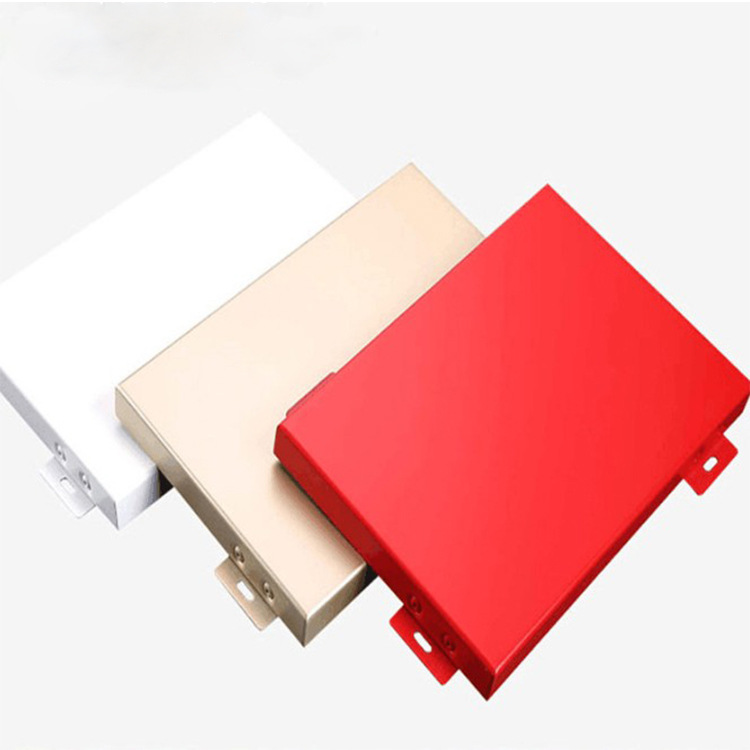

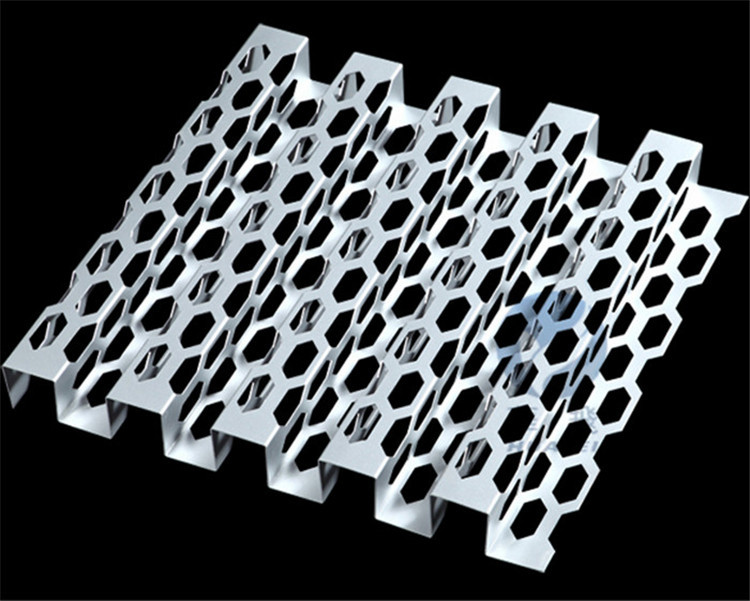

The production process of carved perforated aluminum veneer mainly includes the following steps: selection of raw materials, cutting and processing, surface treatment, carving and punching, etc. The raw material is the basis for making carved perforated aluminum veneer, usually using aluminum alloy sheet with a thickness of about 3mm as the substrate. Cutting processing is the process of cutting aluminum plates into the desired shape and size according to design requirements; Surface treatment includes processes such as spraying and oxidation to improve the corrosion resistance and oxidation resistance of aluminum plates; Carving is the precise carving process of aluminum plates using laser engraving machines or CNC engraving machines; Punching is the process of punching aluminum plates into various exquisite patterns and designs using punching machines.

The application range of carved perforated aluminum veneer is very wide. In addition to being used for indoor and outdoor decoration, such as walls, ceilings, partitions, etc., it can also be used for decoration in commercial places, such as hotels, shopping malls, airports, etc. Through innovative design and creativity, carved perforated aluminum veneer can be combined with other materials to create a more diverse and colorful decoration effect. For example, carved perforated aluminum veneer can be integrated with elements such as wooden furniture and stone flooring to create a unique commercial atmosphere.

Carved perforated aluminum veneer, as a new type of building material, has unique manufacturing techniques and decorative effects. Through continuous technological innovation and application expansion, it will play a more important role in the future field of architectural decoration. We should actively promote and apply this new favorite to add more beautiful scenery to the city.

Customer service QQ

Customer service QQ